High-Quality Cosmetics Production in Germany – Your Cosmetics Manufacturer

Innovation and Tradition Combined – Your Reliable Cosmetics Manufacturer in Germany

In our modern production and office complex in Rudolstadt, completed in 2014, we are setting new standards in cosmetics production. As an experienced cosmetics manufacturer, we offer customized solutions for small and large batches, ranging from 30 to 1,000 kg, in our 287 m² cleanroom. Whether tubes, jars, or custom packaging – we fill and package your cosmetic products with the highest precision and care.

We examine every raw material, every intermediate and end product in our in-house microbiological-analytical laboratory for impurities and only release them for further processing after all tests have been successfully completed. In this way, we give ourselves and our customers maximum security through effective and efficient quality management.

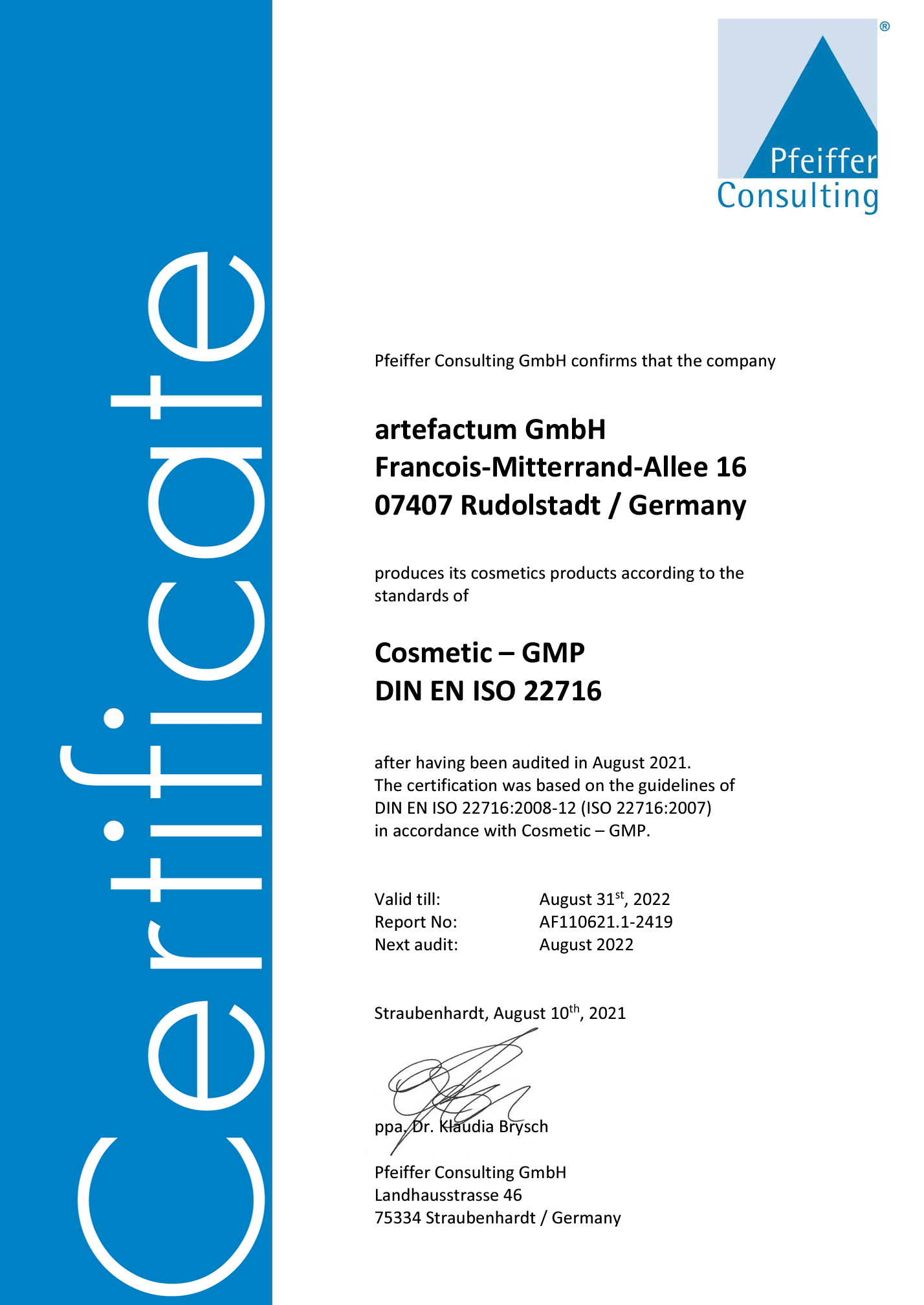

Of course, the production always takes place according to the requirements of the European cosmetics regulation, the GMP standard and 100% in Germany.

Our customers can rely on us with a library of more than 2,500 freely available recipes. Their use is free of charge. We are happy to modify these recipes for you or develop a completely individual formulation according to your specifications.

We can also create the entire documentation and the associated tests for you. For example, safety report (SIB), product information file (PID), CPNP notification, dermatological tests, preservative exposure test (KMBT), clinical studies or evidence of effectiveness for marketing claims can be mentioned here.

Revolutionary Skincare:

CREAM-IN-GEL TECHNOLOGY

Experience the perfect blend of care and aesthetics! Our innovative Cream-in-Gel Technology combines the nourishing power of a cream with the refreshing lightness of a gel – fully customizable in colors, shapes, and active ingredients.

360°

Development

Recipe development

Recipe adjustment

Feasibility studies

Specification book

Prototype

Sampling

360°

Purchase

Raw materials

Packaging

360°

Product Types

Cream

Gel

Oil

Milk

Lotion

Paste

Serum

Care Concentrates

Liquids

360°

Filling of bulk

Plastic or glass jars (5 to 500 ml)

Plastic and aluminium tubes (5 to 500 ml)

Plastic or glass bottles (5 to 500 ml)

Glass vials (2 ml)

Shrink-wrapped masks

all kind of canister, buckets and IBC

360°

Filling of finished products

Artefactum gmbh currently offers you the following four options for filling the different product forms into containers as standard. However, if you wish a special request for the container, artefactum gmbh always endeavors to fulfill it.

Packing

Packing in folding boxes and cardboard boxes

Labeling (front and / or back / wrap-around label)

Encoding

Logistics

Organize transports at home and abroad

Possibility to store special raw materials, packaging, bulk and end products

Shipping by freight carrier, sea or air freight

360°

Quality assurance and documentation

Incoming goods inspections of every raw material in our own microbiological-analytical laboratory

Safe chemical-physical storage of all substances

End product tests in the microbiological-analytical laboratory

Control by external laboratories

Creation of safety assessments

Creation of documentation

Organization of dermatological tests

Implementation of proof of effectiveness

Conducting clinical studies

Registration with CPNP